Our Business

Chemical Products

Everlight AH Sheet

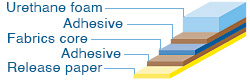

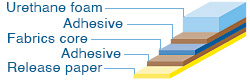

Everlight AH Sheet is a high-performance “sheet of soft polyurethane foam with adhesive” developed by combining soft polyurethane foam technology with the latest adhesive processing technology. Everlight AH Sheet manufacturing process integrates end to end quality control from foam to adhesive, so that it can be used with peace of mind.

Everlight AH Sheet makes it possible to easily attach (adhesive) the desired form to an object.

Main features

- Superior adhesive performance especially on adherends such as ABS materials, painted steel sheets and steel plates.

- Excellent adhesive performance is also exhibited on PP and PE materials, which are generally regarded as difficult to stick to.

- Both long rolls and short plates can be produced.

- Various urethane foam base materials can be selected according to application, including materials with excellent sound absorption and thermal insulation performance.

- Any thickness of urethane foam base material is possible, from 3 mm to 60 mm.

- Post-processing is also available, such as punching into specified shapes, half-cutting, etc.

- Release paper with low peel resistance is used to facilitate workability during use.

Main applications

- Sound-absorbing material around engines of construction machinery

- Sound absorbent around engines of agricultural machinery

- Sound absorbent material inside generators

- Sound absorbent material inside printer enclosures.

- Vehicle pillars, roof insulators, air conditioner surroundings (sealing material), radiator surroundings, inside front mirrors, harnesses.

Type D (direct pull adhesive)

| Part number | Reinforcing core material | Type characteristics | Cross-section view |

|---|---|---|---|

| D-150 (Water-based adhesive) |

– |

|

|

| D-150W (Water-based adhesive) |

– |

|  |

Anti-VOC adhesive products D-150

Until now, when it came to industrial adhesion, including double-sided tape, it was natural to use organic solvents. This is because they are the most effective for fully demonstrating adhesive performance. This time, our company has developed a water-based adhesive that can withstand use in industrial applications.

By replacing organic solvents with water-based solvents, we are promoting consideration for the health of our customers and those involved in production, as well as for the surrounding environment of production plants. It also prevents sick house etc. caused by minute amounts of volatile solvents in housing and vehicle-related applications where airtightness has increased.

R810 "Type-specific characteristics"

| Part number | Reinforcing core material | Type characteristics | Cross-section view |

|---|---|---|---|

| R-800 (Water-based adhesive) |

fabric |

|

|

| R-810 (Water-based adhesive) |

fabric |

|

|